New Opportunities for Rail Freight Systems

Integrated Logistics for Existing Infrastructure

Starting point for the top-down design was a suspension of any preconceived notions of the engineering limitations, and a focus on how the ultimate freight distribution network might look.

Traditional rail systems flourished last century when track architects had ample freedom to lay tracks to satisfy the constraints imposed by the technology of the day. There were two major constraints – minimum track radius and maximum track gradient.

At CF Technologies we have addressed both these limitations to allow rail solutions where they might have previously been excluded.

Track Curvature

Minimum track radius is determined by several factors –

- Maximum Speed of the Rail Vehicles

- Wheelbase — Lateral and Longitudinal

- Axle Arrangement — Fixed or Independent

- Profile of Wheels and Rails

Track Gradient

For metal-on-metal rail systems where several driving wheels may be pulling a multitude of passive bogies, the maximum track gradient is limited to about 2 percent. One of the key benefits in having all-wheel-drive is good traction. This enables vehicles to run at higher than normal gradients.

CFT has combined a set of design features to minimise these limitations.

Since the containers themselves become the vehicle, the wheelbase is approximately half the length of a 40 foot container. By having a direct-drive motor attached to each wheel, there are no fixed axles which add to the wear of both wheels and tracks.

With a vertical centre-of-gravity close to the contact plane between wheels and rails, vehicles remain relatively stable when cornering. Our system is designed for a maximum speed of 20 km/h. Combining these factors allows for a cornering radius down to 90 metres.

Underground Double-Helix

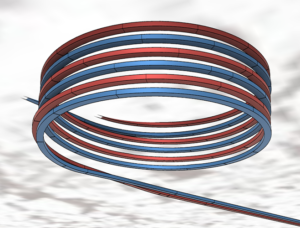

In the Projects section of the website, we mentioned how it is sometimes a necessity for rail lines to drop quite steeply within a confined area. We have capitalised on the tight radius-of-curvature and the increased gradient to produce the double-helix track configuration. This double-helix has been a key element to allow CF Technologies rail solutions in congested dock areas, and a cornerstone of our submissions to several port operators.

In the Projects section of the website, we mentioned how it is sometimes a necessity for rail lines to drop quite steeply within a confined area. We have capitalised on the tight radius-of-curvature and the increased gradient to produce the double-helix track configuration. This double-helix has been a key element to allow CF Technologies rail solutions in congested dock areas, and a cornerstone of our submissions to several port operators.Double-Helix Open-Cut Shell

In the image above, the double-helix is represented as two interwoven helical pipes, not really a practical implementation. The original design specification describes a practical construction technique where the double-helix is installed within an open cylindrical shell that goes to full depth. This would allow quite a variety of construction options. In addition, there could be a few maintenance shafts for later use.

In the image above, the double-helix is represented as two interwoven helical pipes, not really a practical implementation. The original design specification describes a practical construction technique where the double-helix is installed within an open cylindrical shell that goes to full depth. This would allow quite a variety of construction options. In addition, there could be a few maintenance shafts for later use.

Within the shell, supports would be inserted on both sides at regular intervals. The width of the shell is approximately equal to the diameter of the pipes, 5 metres, allowing ample room to install supports into the surrounding soil or rock. The sides of the shell could be lined by stacking prefabricated blocks in place, the blocks being shaped to hold both the rails and the power-lines.

This configuration creates an opportunity to introduce some novel construction techniques. Construction might begin with a circular gantry around the perimeter of the shell. Front-end loaders could circle around below the gantry, getting ever deeper on each revolution. The gantry would then be used to hoist excavated soil to the surface.

Also required in the final installation, although not shown in the illustration, are the light, open-mesh flooring panels that would separate the various levels. This flooring is not essential for normal operation of the container-vehicles, but is extremely important for the safety of construction and maintenance workers.