Projects & Proposals

Two Sites Identified as Potential Pilot Implementations

Armed with the relaxed constraints that CFT can deliver, our initial focus was to investigate where the technology could most effectively be deployed at sites within Australia. Two sites were identified where current technology was unable to provide a solution to an increasingly urgent problem — port congestion. These two sites, Fremantle Dock in Western Australia and Webb Dock in Melbourne, became the subject of preliminary proposals put to the relevant authorities. At the current time, discussions are still in progress.

Fremantle Dock, Western Australia

The existing surface rail to the North of Fremantle Dock is near capacity, and facing increased conflict as the valuable land becomes more desirable for residential purposes. There is also a scheduling problem when freight traffic merges with passenger rail for the rail-bridge that crosses the Swan River.

The CFT proposal is to completely eliminate all rail-freight infrastructure to the North of Fremantle Dock, and reroute freight-traffic underground, directly through Canning Vale to the Kewdale rail-terminal. This proposal was very well received from an engineering perspective, but political developments are delaying the project at this time.

The biggest challenge facing Fremantle Dock was how to get down to depth below the Swan River in the limited space available. The cornerstone of the CFT proposal was a double helix rail configuration within an open-cut cylindrical shell.

Several CFT design features allow for unprecedented flexibility when planning new rail architecture. The tight radius of the double-helix is made possible by the short wheel-base for the container vehicles, plus the split-axles and low centre-of-gravity ensure good traction and dynamic stability.

View video about Fremantle Dock

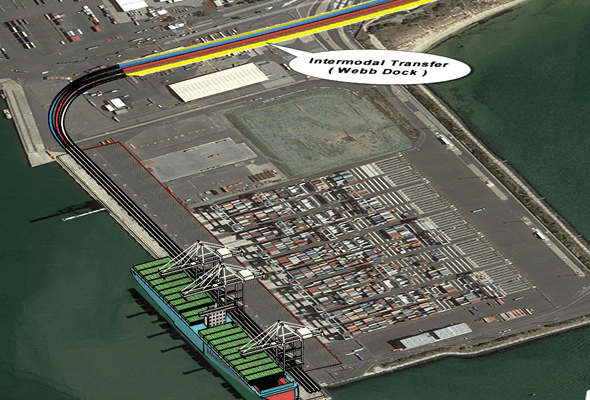

Webb Dock, Victoria, Australia

As with Fremantle Dock, Webb Dock has limited real-estate to accommodate a rail-line that drops to depth and passes under a river to connect with the existing distribution network. The double-helix configuration can be used on both sides of the Yarra River to accomplish the connection.

By providing a continuous flow of containers to and from the ships, the CFT system eliminates the need for a temporary storage facility, and increases efficiency by removing double-handling. The enclosed pipe design allows container traffic to pass through sensitive residential areas with minimal impact.

There are three open-tube channels shown running next to the ship in the graphics — two channels are for container traffic and an additional service channel for storing and feeding the Detachable Drive Units to the cranes when they are needed for unloading.

Part of the CFT design is a modification that can be made to any standard ship-to-shore crane. The main gantry uses a Spreader to move containers between the ship and a shelf mid-way up the crane structure. There are two secondary gantries that are responsible for moving the containers between the shelf and the transportation device, and also provide an efficient mechanism for connecting DDUs with the containers.